Caster — how do I find the right one?

There are casters like sand by the sea, in different sizes, materials, for different purposes, for different load capacities … nowadays there are many types to buy. It is therefore difficult to find the right casters for a construction or project. The questions below should help you to make the right choice.

Procedure

- Location: Where should the caster be used?

- Location: Are there any special regulations at the location which must be observed (food industry, chemical laboratory, etc.)?

- Location: Are there special environmental conditions at the location (tropical climate, high salt content, etc.)?

- Load capacities: What is the maximum weight the roll should withstand?

- Material: Which material is required (stainless steel, ESD-compatible, high temperatures, etc.)?

- Floor condition: What does the floor condition look like (industrial hall, parquet, carpet, gravel floor etc.)?

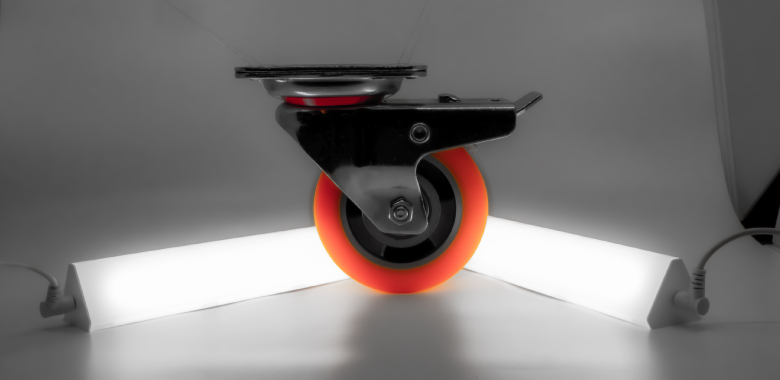

- Accessories: What type of caster do you need (steering caster, steering caster with brakes, fixed caster)?

- Dimensions: Are there specifications regarding the installation dimensions (height, fixing points, etc.)?

Detailed questions

Point 1 is about deciding where you want to use your machine, furniture or other construction. If your construction is used in a factory, in an office, a workshop, a dentist’s office, a bakery, a trust office, in the garden, on the outside parking lot, outside under the canopy, in the desert, by the sea … there are no limits to your imagination.

Point 2 is about finding out whether you are subject to special regulations, as is the case in the chemical or food industry, for example in a bakery. You should know the rules for your particular area and the requirements that apply.

Point 3 deals in more detail with the climate, or rather the temperature. Do the casters have to withstand special temperatures? Are the casters used, for example, in a freezing plant for bakery products, meat, ice cream, medicines, etc.? Or are the casters used at very high temperatures in ovens, baking plants or others? Systems close to the ocean also have to withstand other stresses than those we are familiar with in Central Europe. The air contains salt, which can have a negative effect on steel and aluminium plants.

Point 4 deals with the load carrying capacity of the casters. How much weight must a single caster withstand? How much weight does the complete machine or your furniture weigh under full load? Is there an uneven weight distribution? The casters must also be able to withstand such an uneven weight distribution.

In point 5, you should recall the special regulations. Are there material specifications for your area of application? Must stainless steel be used because galvanized steel does not conform to the regulations? Or do you even need electrostatic dissipative products?

Point 6 is about deciding where you want to use your machine, furniture or other construction. Do the casters run on a factory floor, on concrete, on carpeting in an office or on a wooden floor at home? Or is your construction used outside in the garden on a gravel path, near the sea or in a chemical or food factory? Do you use the casters in a bakery, butcher’s shop or trust office? — You should be aware of where they are used, as this is the only way to achieve the best price/performance ratio so that you can enjoy the product for a long time.

Point 7 is about finding out whether you need swivel casters, swivel casters with brakes, fixed casters or a combination of the variants listed.

Probably the most technical point is point 8, which is ultimately about the installation dimensions. How big should the caster be? What is the maximum installation height? Do you need casters with a top plate to attach to your machine or furniture, or do you need a stem or a bolt hole? What thread fits your machine? Are there specifications for the wheel width? Must the rollers contain ball bearings or are slide bearings sufficient?

Final judgement

Finding the right caster is not as easy as it might seem at first glance. It is therefore worth contacting a specialist at an early stage so that he can perhaps define this “banal” point at an early stage at first glance, so that the substructure of the machine also matches the comfort of the rest of the machine and supports and perhaps even expands its function.