Leveling casters from Sigerist GmbH - directly from the manufacturer

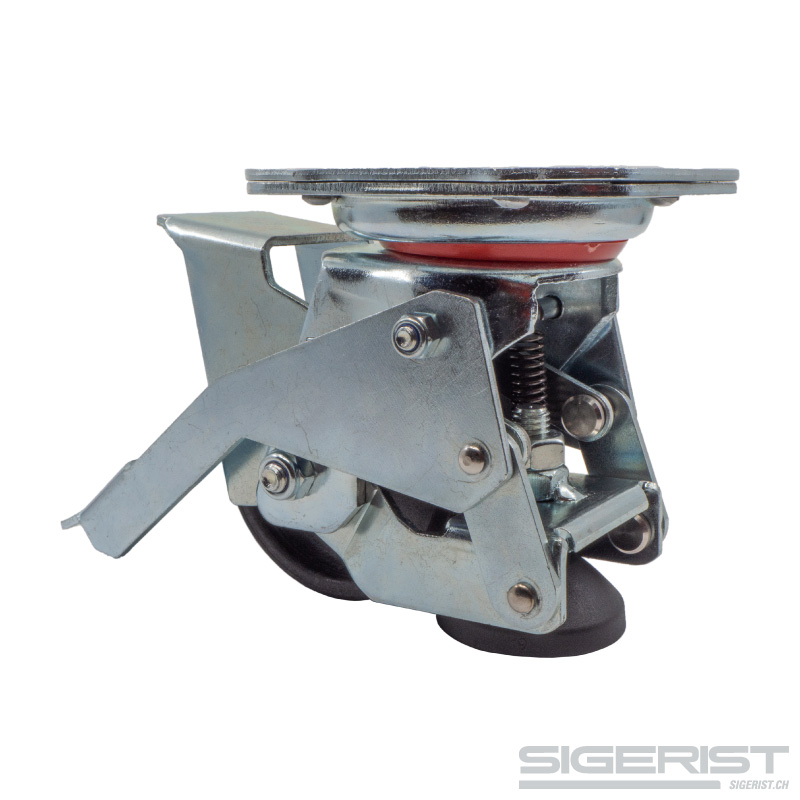

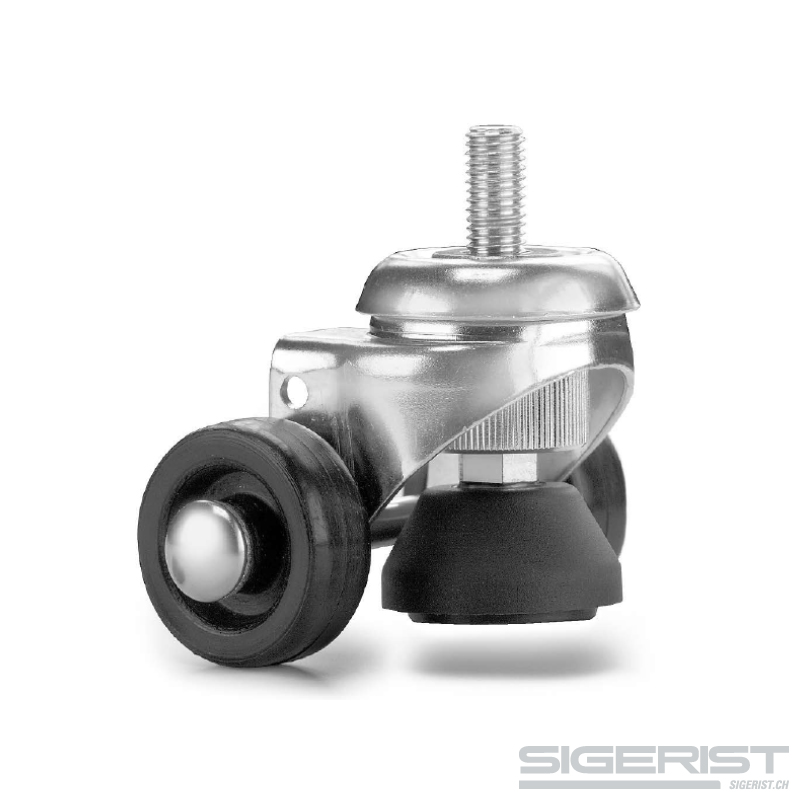

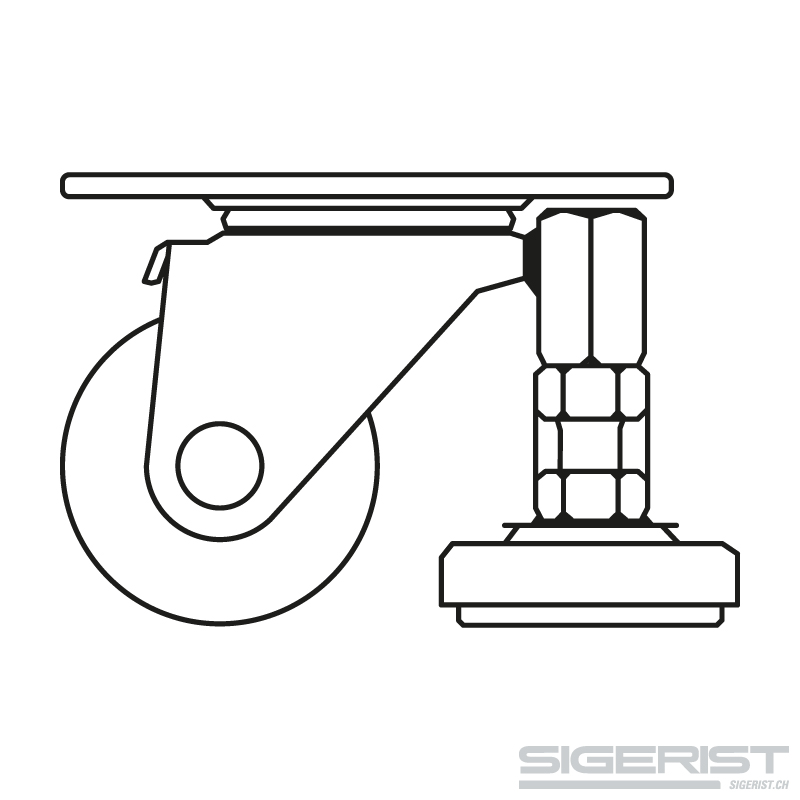

Different types

Leveling casters are a combination of a caster and a leveling foot. They are available with or without foot pedal.

They serve the purpose for example to place work tables, racks and measuring devices safely on a machine foot, but still have the possibility to move them quickly and easily, without the use of forklifts, forklift trucks, cranes etc..

Machines, working platforms, tables, shelves, test systems, measuring devices etc. can be moved quickly and easily to a desired location and fixed there again. Leveling casters are also available with leveling feet. This makes it easy to compensate for uneven floors. Leveling casters are available with plate, with stem fitting or also with back hole. There exists a solution for every application.