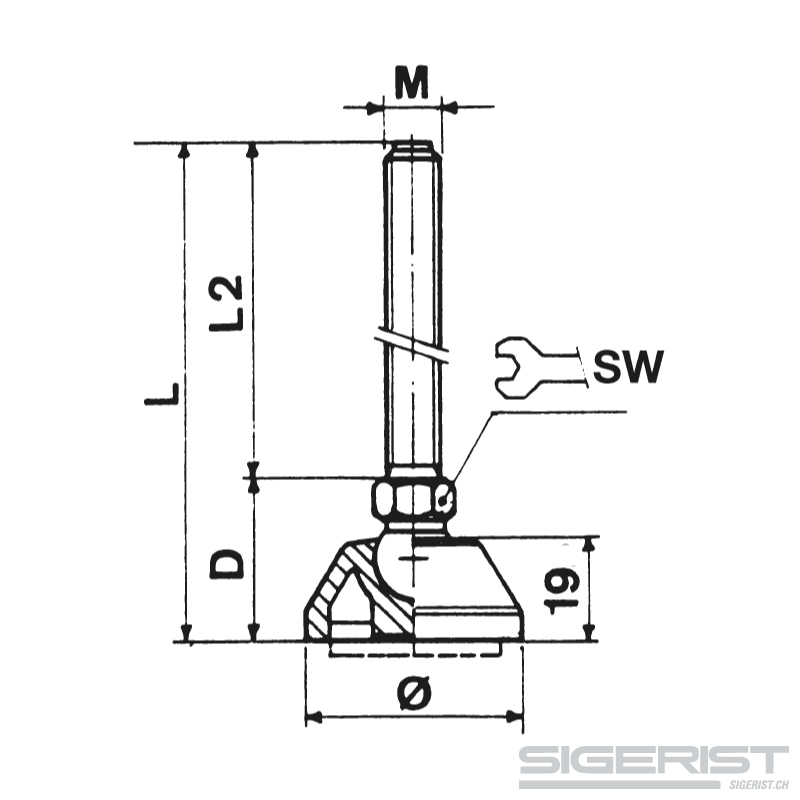

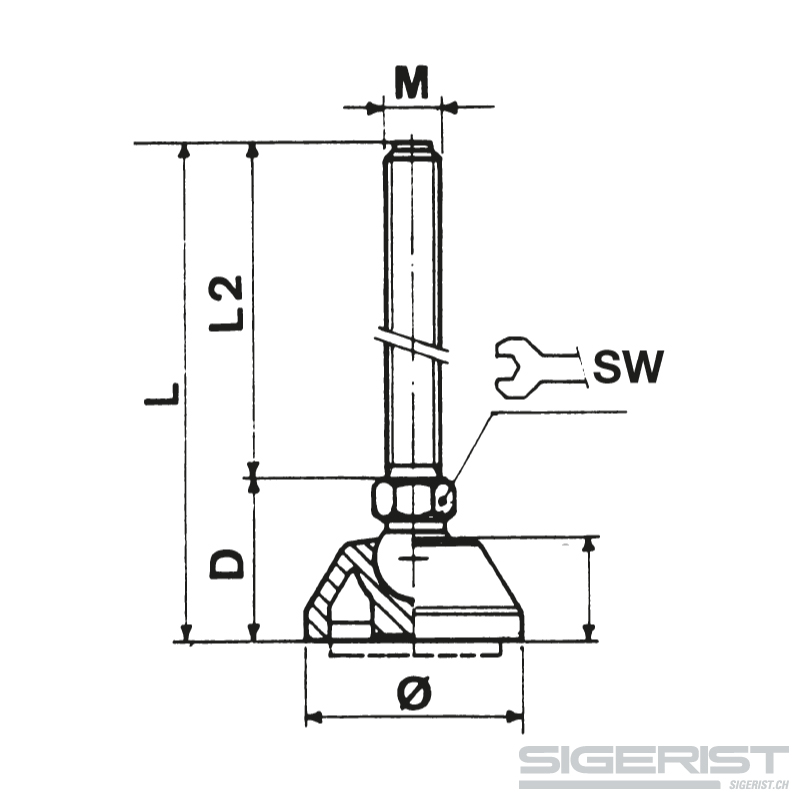

Machine feet from Sigerist GmbH - directly from the manufacturer

Various Types

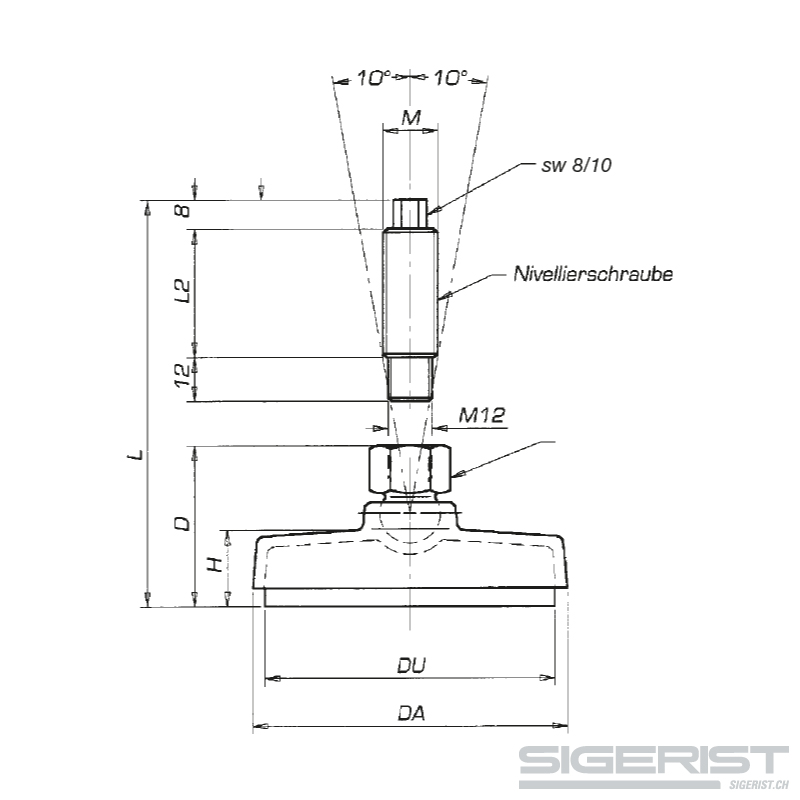

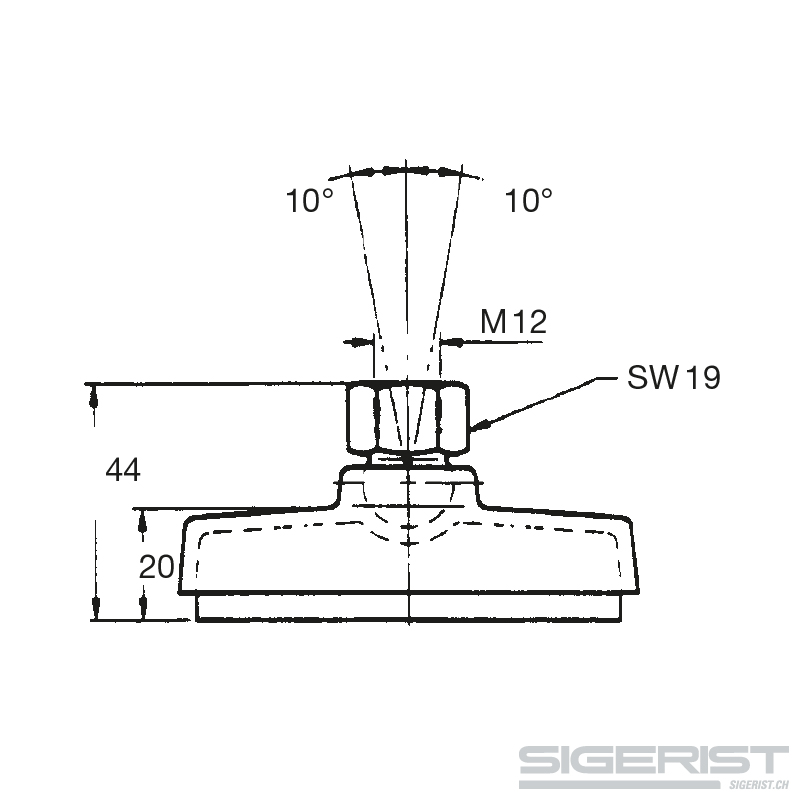

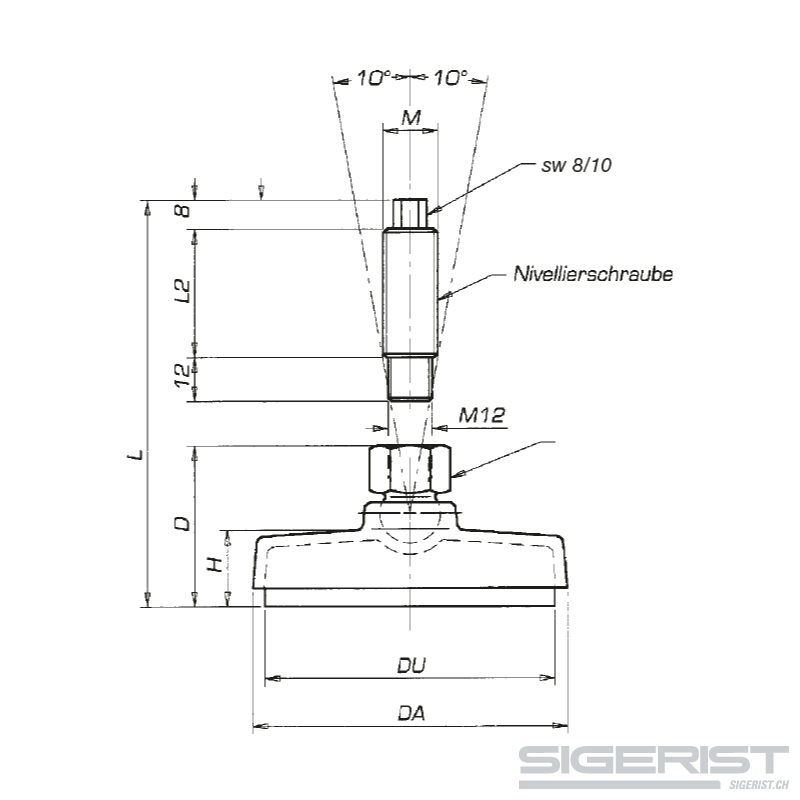

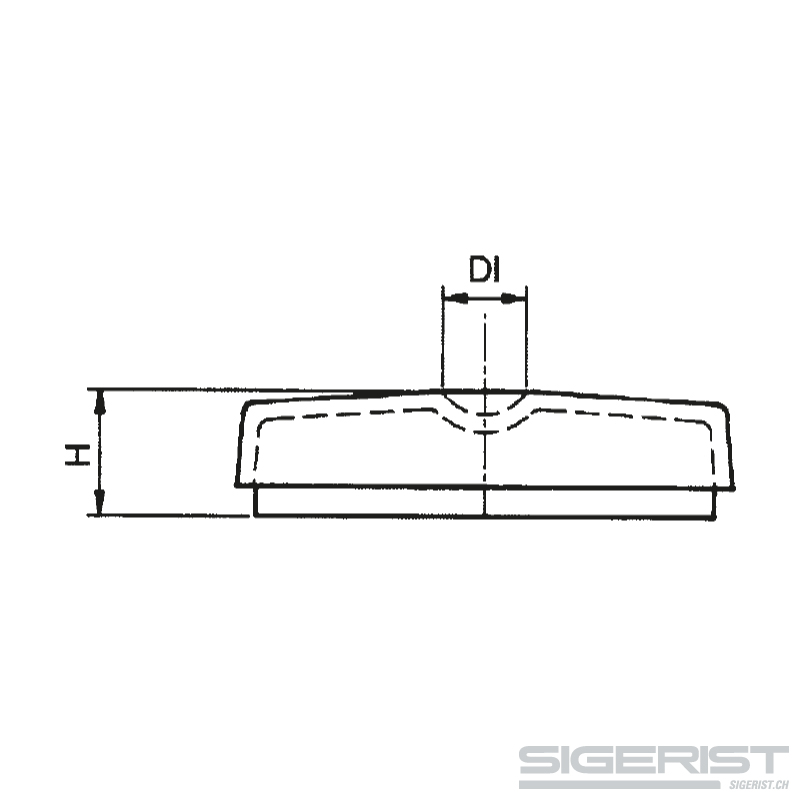

Machine feet come in a wide variety of designs: different load capacities, different threads, different screw lengths, different materials, rigid machine foot, articulated foot, vibration-damping, with anti-slip sole etc.