Lifting systems from Sigerist GmbH - directly from the manufacturer

What can a lifting system do and where can it be used?

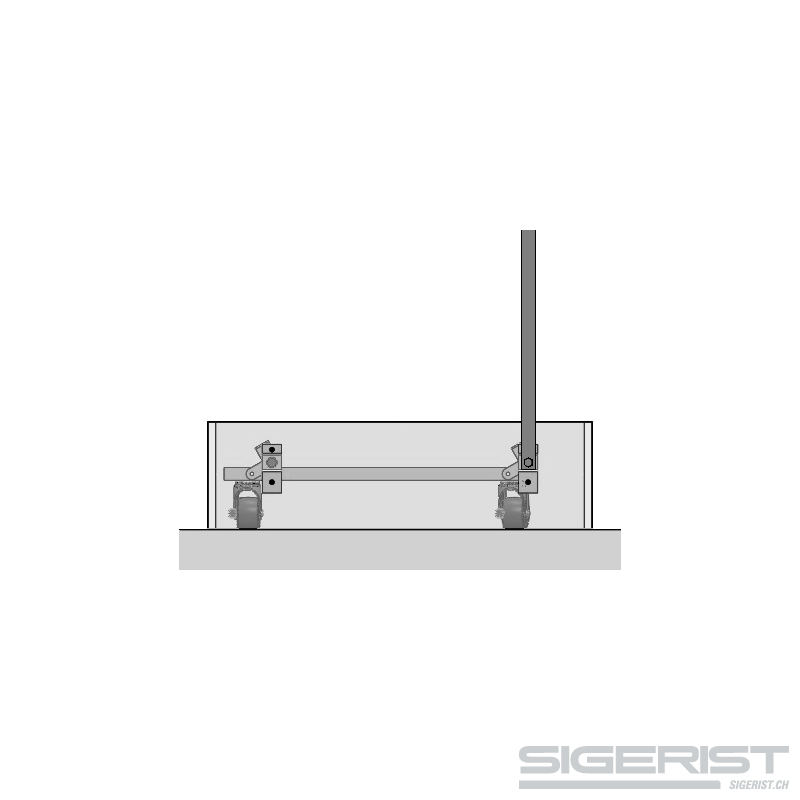

Lifting systems (also called leveling caster systems) have the following functions:

- drive

- secure parking

- levelling (e.g. levelling caster system Synchro-LIFT)

- synchronous switch from "drive" to "safe shutdown"

Lifting systems serve to make things mobile and flexible. They are suitable where things have to be moved often, quickly and easily.

Lifting systems are used, for example, for measuring instruments which are used on different production lines and therefore have to be mobile. But they are also used for work stairs, work tables, workbenches, furniture, shelves, sideboards and much more.