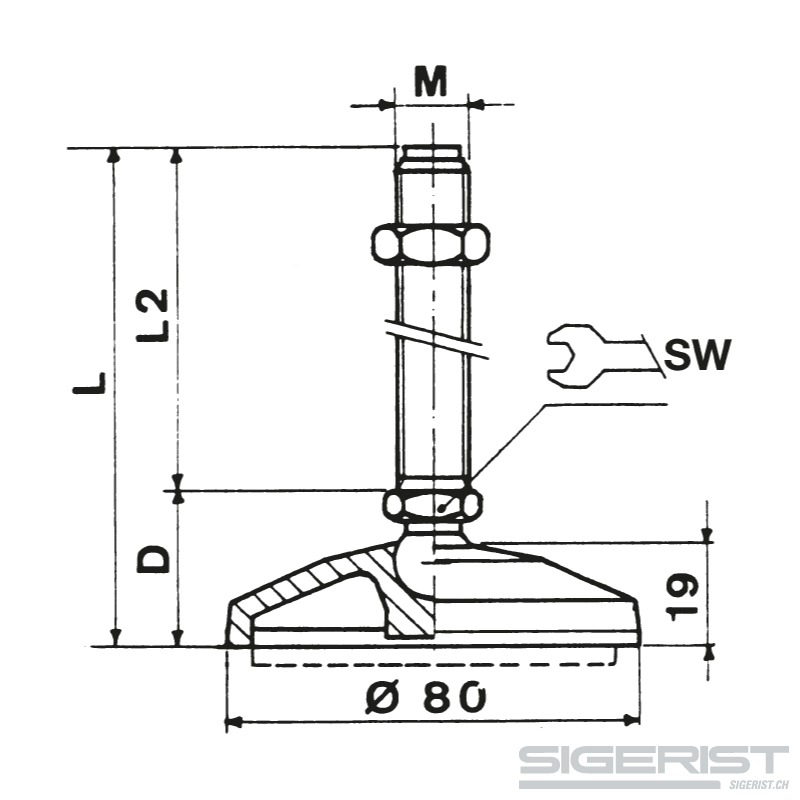

Machine foot with floor mounting, galvanized steel, diameter 80 mm – hinged base

The machine foot with floor mounting galvanized steel diameter 80 mm. – The machine foot is designed for loads up to 1000 kg per foot. It consists of a threaded rod with ball joint and can therefore adapt well to uneven ground.

- Description

- Properties

- more detailed information

- Contact & Inquiries

Description

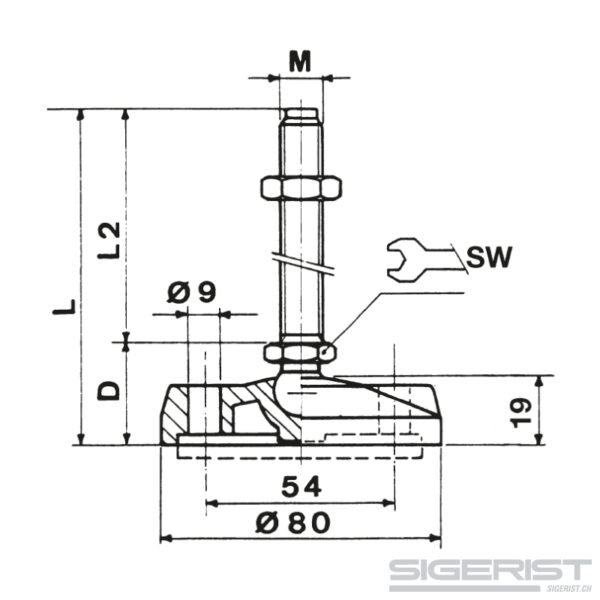

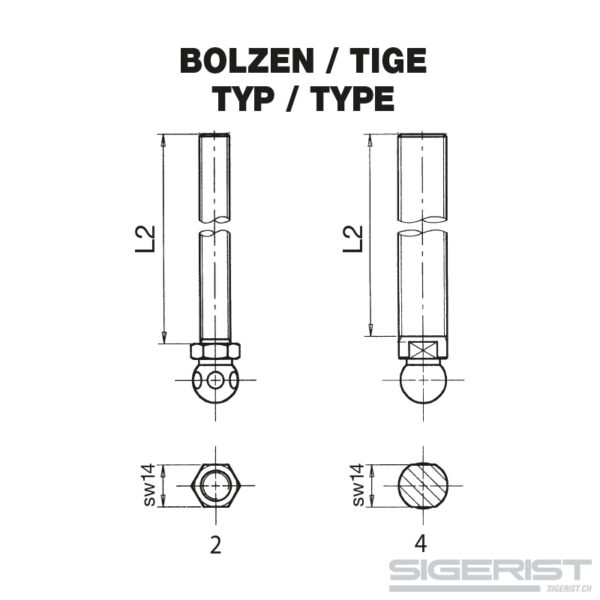

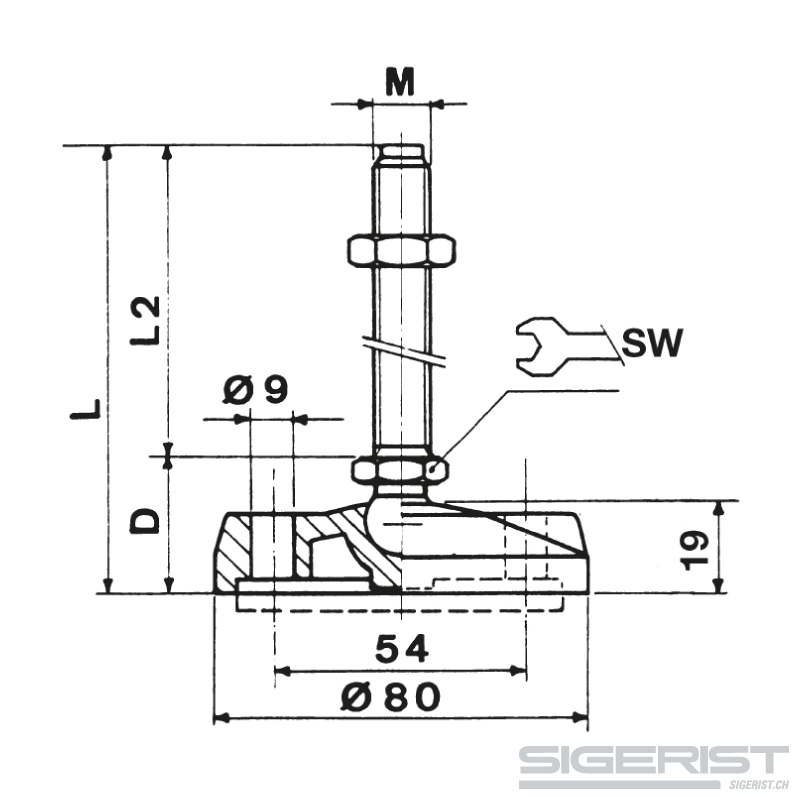

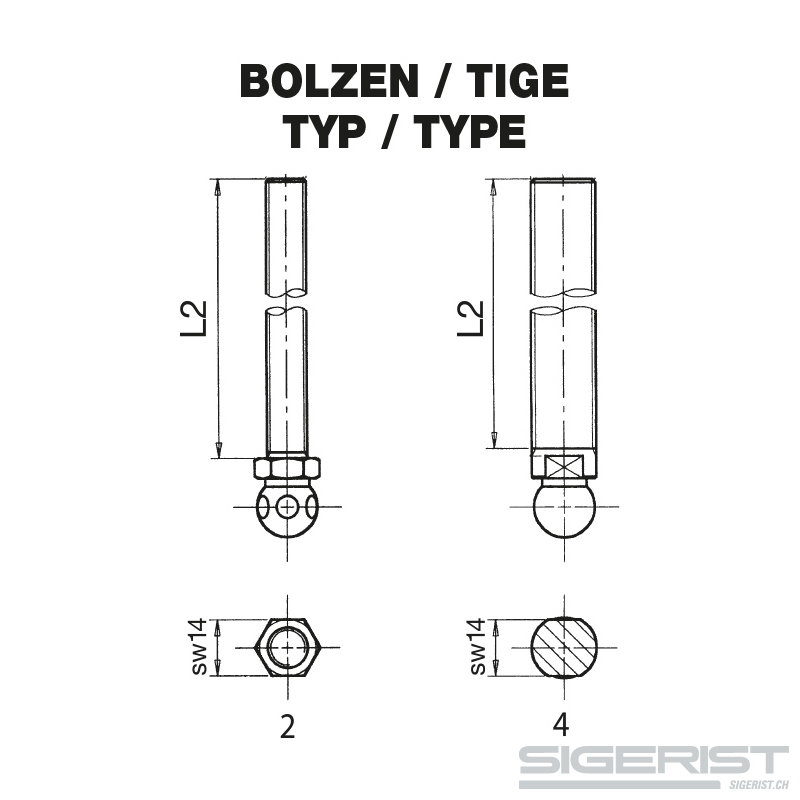

The Machine foot with floor mounting, galvanized steel, diameter 80 mm – hinged base – is available in the versions listed below.

| Type | Thread x L2 | D | Length L | SW | Bolt Type | |

|---|---|---|---|---|---|---|

| mm | mm | mm | kg | |||

| S80M8x50Sa | M8 x 50 | 28 | 78 | 14 | 2 | 1000 |

| S80M8x70Sa | M8 x 70 | 28 | 98 | 14 | 2 | 1000 |

| S80M10x50Sa | M10 x 50 | 28 | 78 | 14 | 2 | 1000 |

| S80m10x70Sa | M10 x 70 | 28 | 98 | 14 | 2 | 1000 |

| S80M10x125Sa | M10 x 125 | 28 | 153 | 14 | 2 | 1000 |

| S80M12x50Sa | M12 x 50 | 28 | 78 | 14 | 2 | 1000 |

| S80M12x70Sa | M12 x 70 | 28 | 98 | 14 | 2 | 1000 |

| S80M12x125Sa | M12 x 125 | 28 | 153 | 14 | 2 | 1000 |

| S80M16x70Sa | M16 x 70 | 28 | 98 | 14 | 4 | 1000 |

| S80M16x120Sa | M16 x 120 | 28 | 148 | 14 | 4 | 1000 |

| S80M16x160Sa | M16 x 160 | 28 | 188 | 14 | 2 | 1000 |

You will find an overview of all machine feet here.

Foot plate

- reinforced polyamide

- black

Threaded rod with ball joint

galvanized steel

Floor mounted machine feet for high demands

In many areas, the machine foot can do without fastening. This is always the case when low horizontal loads are to be expected. Anti-slip soles or rubber pads with suction profiles are used here. Permanent horizontal loads, however, cause machines and factory equipment to tend to leave their position. If this is additionally favoured by a slope of the ground, anchoring in the ground by means of anchor bolts can no longer be avoided.

However, this is not a problem either, because it is much easier to anchor a machine foot than it was several decades ago. The time of the embedded anchor bolts is long past.

The floor fixing of modern machine feet

Extensive mortising work for anchor holes is finally a thing of the past. Even weeks of waiting until the fresh concrete has set sufficiently are a thing of the past. Today, normal anchors or, in extreme cases, heavy-duty anchors, which allow production to commence immediately after anchoring, are sufficient. The height and balance settings can also be adjusted steplessly using the adjusting screws. This means that there is no need for cumbersome alignment with spacers or the like. The set screws are made of threaded rods with metric threads from M 8 to M 24 and are optionally made of galvanized steel or stainless steel.

For secure fastening, the foot plates, made of high-strength plastic, are provided with corresponding holes for anchor bolts of a specified size. Foot plates and anchor bolts correspond to the expected load, which can be up to 4000 kg. In order to ensure precise marking of the anchor bore, each machine foot must be precisely positioned beforehand. The safest method is a direct tracing of the holes after the machine feet have already been screwed under. The machine must then be moved to the side again. A double amount of work, which should be avoided especially with units weighing several tons. This can be achieved by using a template made of hard cardboard. Any measuring error is thus reliably ruled out. Once the dowel holes have been drilled, the machine is positioned, levelled and tightened.

A safe ground mounting depends on the correct size determination

When choosing the right machine foot size, several factors must be taken into account.

For example, it is not sufficient to divide the total weight of the machine or unit by four if there are four anchor holes. Weights of machines and devices are not evenly distributed, so the load must be known for each individual machine foot. In addition, there are one-sided loads caused by the material to be machined as well as shocks or vibrations, which must be taken into account. For safety reasons, the decision should always be made on a machine foot of the next higher load class.