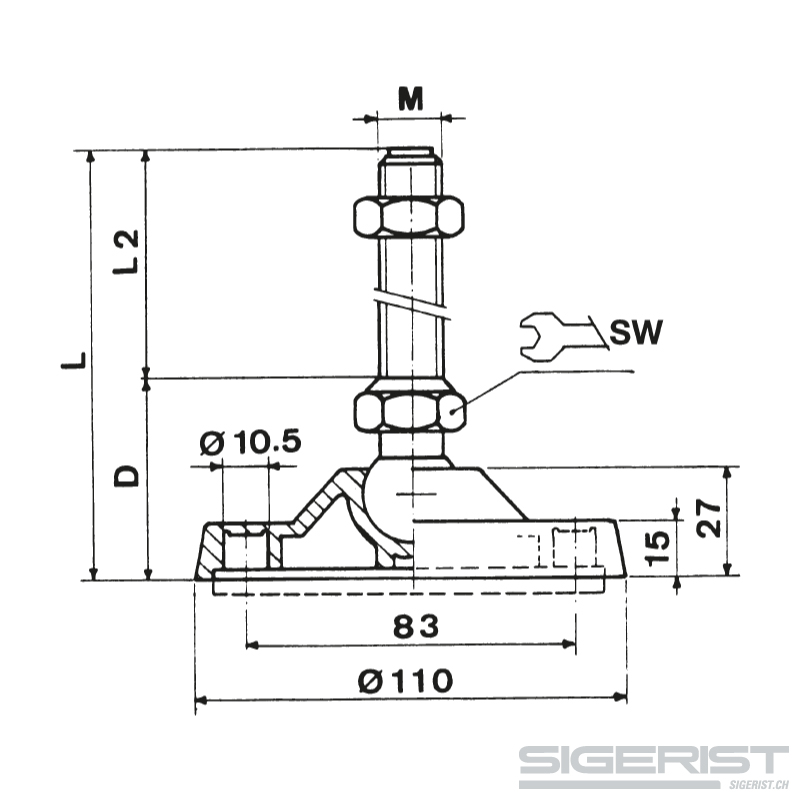

Machine foot galvanized steel diameter 110 mm – hinged foot

The machine foot is made of galvanized steel with a diameter of 110 mm. The articulated base is designed for loads of up to 1800 kg per foot. It consists of a threaded rod with ball joint and can therefore adapt well to uneven ground. The foot plate is also prepared for floor mounting with a hole for cutting out with a diameter of 10.5 mm.

.

- Description

- Properties

- more detailed information

- Contact & Inquiries

Description

The machine foot galvanized steel diameter 110 mm – hinged foot is available in the versions listed below.

| Type | Thread x L2 | D | Length L | SW | Bolt Type | |

|---|---|---|---|---|---|---|

| mm | mm | mm | kg | |||

| S110M12x50S | M12 x 50 | 46 | 96 | 24 | 2 | 1800 |

| S110M12x100S | M12 x 100 | 46 | 146 | 24 | 2 | 1800 |

| S110M12x150S | M12 x 150 | 46 | 196 | 24 | 2 | 1800 |

| S110M16x50S | M16 x 50 | 46 | 96 | 24 | 2 | 1800 |

| S110M16x100S | M16 x 100 | 46 | 146 | 24 | 2 | 1800 |

| S110M16x150S | M16 x 150 | 46 | 196 | 24 | 2 | 1800 |

| S110M20x100S | M20 x 100 | 46 | 146 | 24 | 2 | 1800 |

| S110M20x150S | M20 x 150 | 46 | 196 | 24 | 2 | 1800 |

| S110M20x200S | M20 x 200 | 46 | 246 | 24 | 2 | 1800 |

You will find an overview of all machine feet here.

Foot plate

- reinforced polyamide

- black

- with prepared hole for cut-out (diameter 10.5 mm) for ground mounting

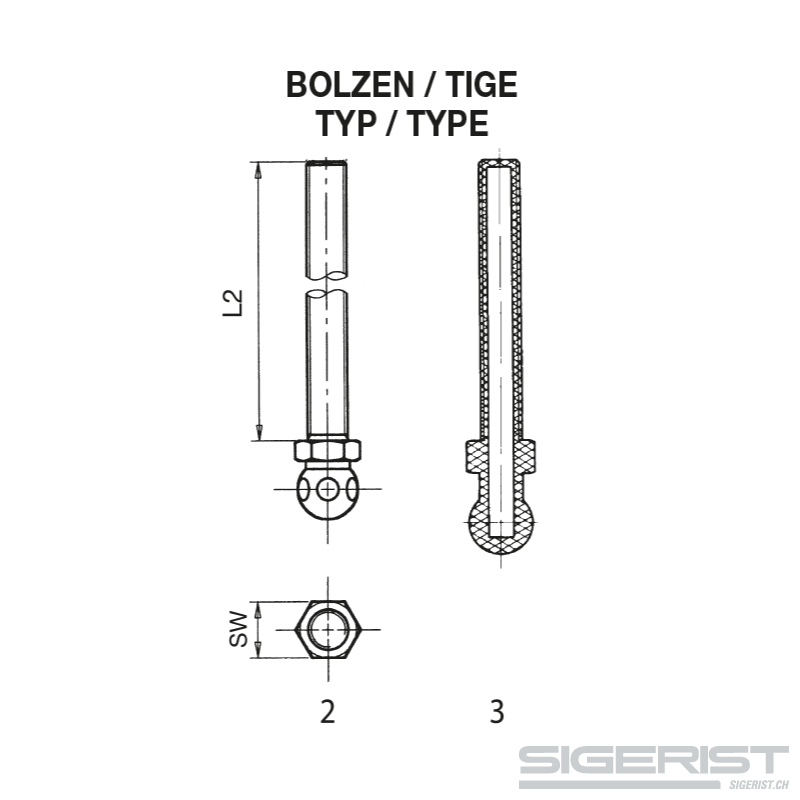

Threaded rod with ball joint

Galvanized steel

Machine foot and machine

The function and effectiveness of machines depend on safe anchoring and precise alignment. The times in which these conditions had to be created by elaborate foundation work and time-consuming levelling with compensation plates in conjunction with embedded anchor bolts are long gone. With the help of a highly innovative development in the middle of the twentieth century, many requirements could be combined in a particularly economical way with just one machine element. A machine element came onto the market under the name “machine foot”, which not only simplified the anchoring of machines, but also the stepless levelling, even in relatively unfavourable subsoil conditions. In situations with low loads and vibrations, anchoring can often be dispensed with.

The machine base in application-dependent sizes and designs

machine feet consist of a round foot plate made of heavy-duty plastic and a threaded rod anchored in it made of galvanized steel or solid stainless steel. In special situations, the threaded rod can also be arranged eccentrically if the given circumstances only permit one-sided fastening. Another variant is the use of articulated feet, which are suitable for compensating for unevenness and floor inclinations of 10 degrees and more.

Size and design for machine feet depend on the expected load as well as the soil conditions. The diameters range from 40 millimeters to 123 millimeters. Thread diameters from M8 to M24 and lengths up to 200 millimetres are available for threaded rods. In terms of load capacity, the field ranges from the smallest foot with 500 kg to 3500 kg for the largest foot. All foot plates can be equipped with an anti-slip sole.

However, there are several factors to consider when selecting the correct machine foot. For example, a low load does not always mean that a small foot plate is sufficient. Depending on the condition of the underbody and the varying load, a large foot rest must often be selected, which then also manages without anchoring with an anti-slip sole. Threaded rods with small diameters are also available for large foot plates.

In the case of machines and highly loaded work tables, special attention must be paid to changing point loads. In addition, the dead weight of machine constructions is by no means evenly distributed. Therefore, the machine weight and that of the workpieces to be expected must be considered separately for all machine feet.