Machine foot galvanized steel diameter 123 mm – hinged foot

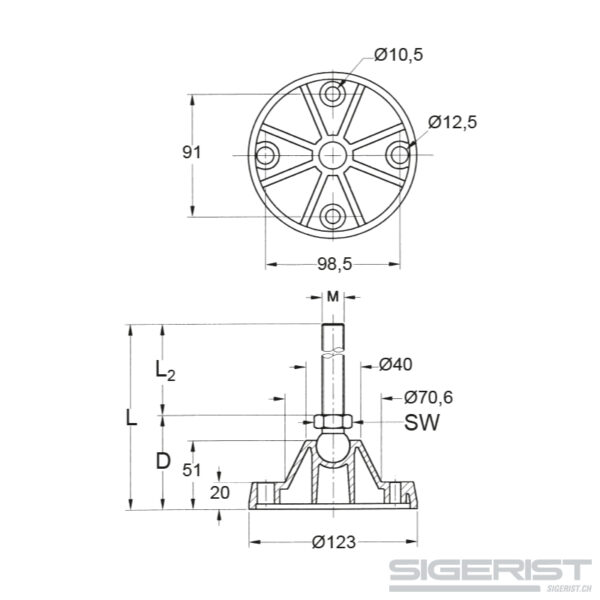

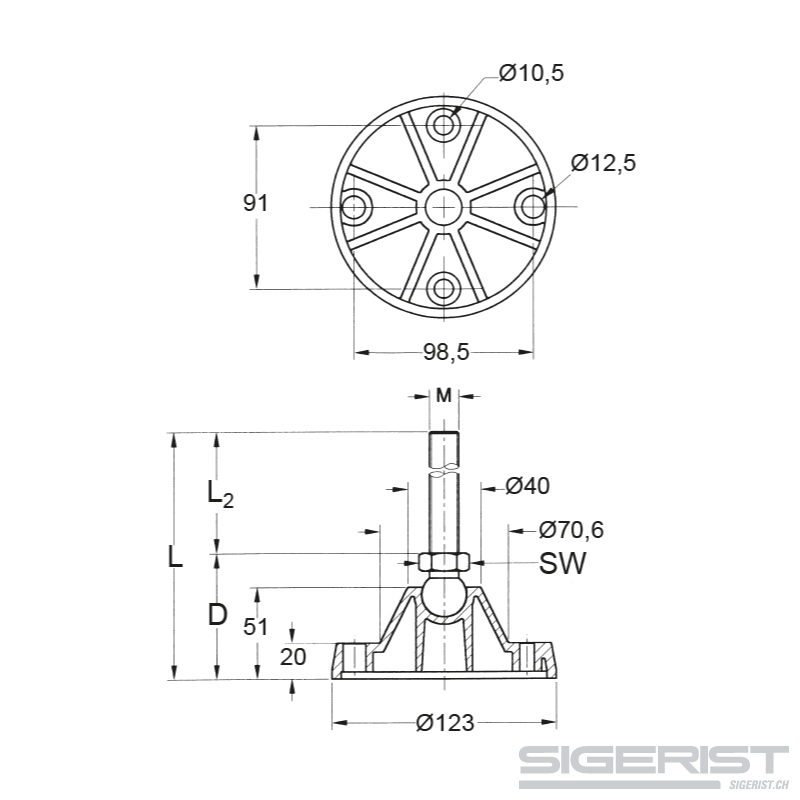

The machine foot is made of galvanized steel with a diameter of 123 mm. The articulated base is designed for loads of up to 2000 kg per foot. It consists of a threaded rod with ball joint and can therefore adapt well to uneven ground. The foot plate is also prepared for floor mounting with a hole for grooving with a diameter of 10.5 mm or alternatively with a diameter of 12.5 mm.

- Description

- Properties

- more detailed information

- Contact & Inquiries

Description

The machine foot galvanized steel diameter 123 mm – hinged foot is available in the versions listed below.

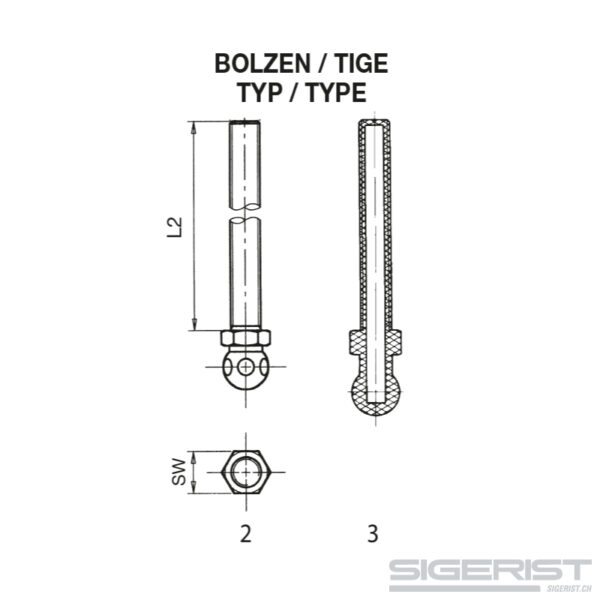

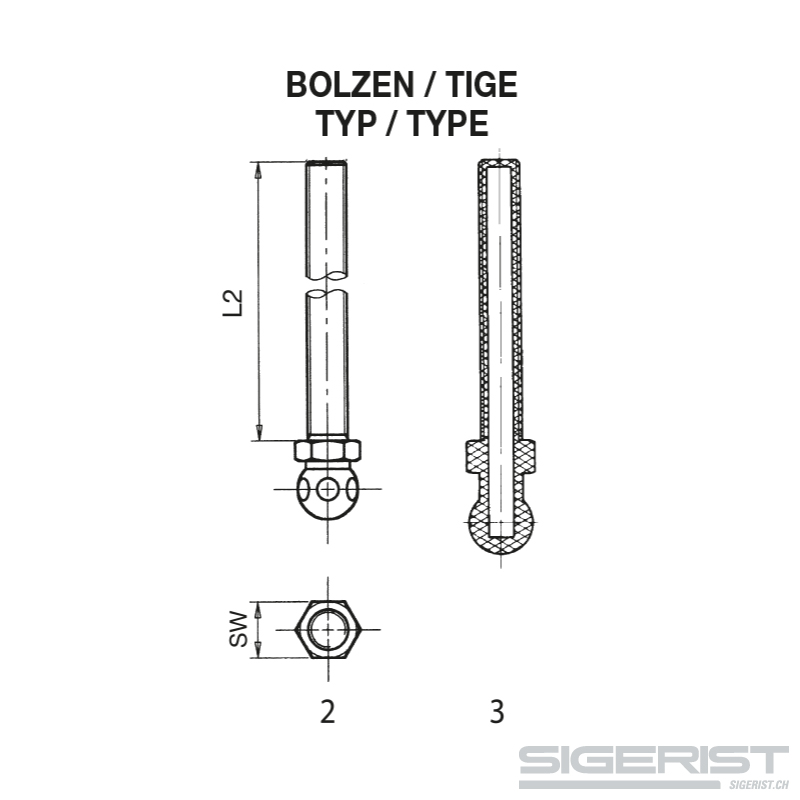

| Type | Thread x L2 | D | Length L | SW | Bolt Type | |

|---|---|---|---|---|---|---|

| mm | mm | mm | kg | |||

| S123M12x50S | M12 x 50 | 70 | 120 | 24 | 2 | 2000 |

| S123M12x100S | M12 x 100 | 70 | 170 | 24 | 2 | 2000 |

| S123M12x150S | M12 x 150 | 70 | 220 | 24 | 2 | 2000 |

| S123M16x50S | M16 x 50 | 70 | 120 | 24 | 2 | 2000 |

| S123M16x100S | M16 x 100 | 70 | 170 | 24 | 2 | 2000 |

| S123M16x150S | M16 x 150 | 70 | 220 | 24 | 2 | 2000 |

| S123M20x100S | M20 x 100 | 70 | 170 | 24 | 2 | 2000 |

| S123M20x150S | M20 x 150 | 70 | 220 | 24 | 2 | 2000 |

| S123M20x200S | M20 x 200 | 70 | 270 | 24 | 2 | 2000 |

You will find an overview of all machine feet here.

Foot plate

- reinforced polyamide

- black

- with prepared hole for cut-out (diameter 10.5 mm or 12.5 mm) for floor mounting

Threaded rod with ball joint

galvanized steel

Machine foot – its places of use

The machine foot and its places of use

From small businesses to industry, various types of equipment are used in all areas of production. These include machines, plants, devices or such simple things as work tables. However, effective use is not possible without clean alignment and stable stability that can withstand all loads and vibrations. In earlier times, this often required extensive foundation work and substructures for anchoring. Thus a time-consuming and cost-intensive action, which multiplied depending upon number of the objects to be anchored within a plant still. In the middle of the twentieth century, a rational and economical solution created an innovative development which represented a breakthrough under the name “machine foot”.

The machine foot as a groundbreaking innovation

machine feet perform a large number of special tasks simultaneously in this context and can therefore be regarded as universal elements. Two requirements are particularly important here: levelling, compensation for uneven floors and anchoring.

With regard to levelling the possibility of stepless height adjustment is of course one of the decisive advantages of the machine foot. This is achieved by a threaded rod anchored in the footplate.

For larger uneven surfaces or even inclined surfaces with an inclination of 10 degrees or more, articulated feet are used. These universal machine feet have a ball joint in the foot plate which automatically adapts to the ground conditions.

For anchoring the foot plates, from 80 mm diameter, are provided with holes for anchor bolts. This enables an exact fixing and anchoring of the machine or plant frame, simply by inserting dowels into concrete or tapped holes in steel subframes. Smaller plates have no anchor holes, but can be provided with an anti-slip sole.

Various ranges and locations for optimum use

The variety of applications for machine feet is almost infinite. There is hardly a production branch in industry, trade or the service sector where this innovative machine element is not used.

This includes machines, motors and aggregates in wood, plastic and metal processing or the food industry as well as pumps, blowers and cooling machines in large air-conditioning systems. Very often, in addition to anchoring and levelling, vibration damping must also be taken into account. The automotive industry, for example, also occupies a large area, where due to constantly changing models, many devices and systems are subject to relatively frequent changes.

The other areas of application also include CNC-controlled machine tools and machining centres as well as printing machines or computer-controlled production systems in the furniture industry. These highly sensitive production units are particularly dependent on precise levelling and vibration-free anchoring.

But also for simple applications, such as work tables or shelves and racks, machine feet can make a considerable contribution to facilitating work and thus to more rational working.