Which wheel tread is the right one for my application?

Plastics such as polyamide (PA), polyurethane (PU) or rubber are also used in many other ways besides their intended purpose as wheel tread.

Synthetic fibres made of polyamide are often used to manufacture a wide variety of textile products. Goods such as clothes, sails, ropes, fishing line and much more are made from the material. It is also used to make many household items and technical components. These can be dowels, housings, kitchen utensils and even machine parts, to name just a few examples.

Polyurethane, on the other hand, is often used as foam. This, for example, as a common household sponge or as padding material for mattresses and seat covers. PU foam is also used for heat and sound insulation, in paints and coatings and for the production of elastic to hard-elastic parts, moulds and tools.

Rubber is used in particular for the production of tyres, but is also used, for example, as a material for the production of belts, rubber boots, shoe soles and rubbers.

Now which wheel tread is best suited to my application?

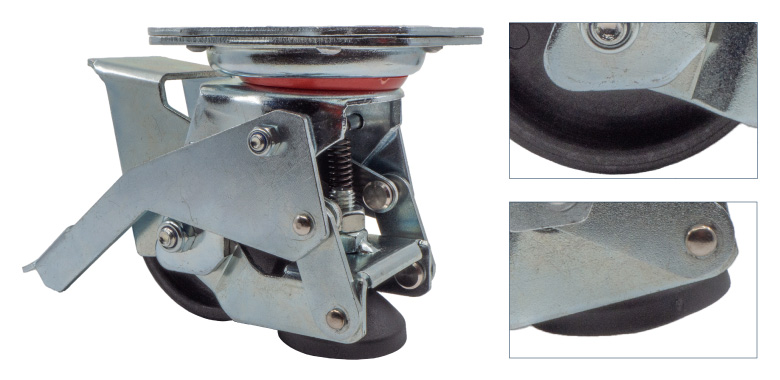

There are some differences in the properties of the materials mentioned above and yet all of them can be used to tyre wheels and castors. But where are the differences in use? Which material is better suited for which surface or purpose?

Polyamide

Polyamide is very hard. PA wheels therefore have low grip. The starting and rolling resistance is also very low. For moving large loads, this means that the necessary effort is lower. However, due to their hardness, polyamide wheels can damage less resistant floor coverings such as tiles and cause noise emissions. Polyamide wheels are resistant to various chemical substances and the low wear allows for a long service life. On hard floors, manoeuvring or braking will not leave marks. On less hard floor coverings such as wooden or plastic floors, streaks or nicks may remain.

Polyurethane

Polyurethane wheels have a high load-bearing capacity and can be used without problems even under dynamic loads. The material is extremely resistant to physical impact, has resistance to grease and oil as well as acids and bases, and withstands temperatures from -20 °C to +80 °C. It is softer than polyamide. It is softer than polyamide and therefore offers good adhesive properties and noise damping. Polyurethane castors do not stain and, like polyamide wheels, leave no marks on the surface.

Rubber

Solid rubber wheels are somewhat less robust and suitable for light to medium loads. They are gentle on the ground and are shock-resistant as well as vibration-absorbing, which makes for pleasant and quiet movement. They are weather-resistant and are therefore also ideally suited for outdoor use. When used indoors, please bear in mind that some solid rubber wheels may rub off and leave marks on the floor covering.

You can find an overview of our wheels/castors here.

We will be happy to advise you if you are unsure about which wheel is best for you. Contact us now.