How to find the right polyamide wheel for your needs

Polyamide wheels, also known as nylon wheels, are indispensable in many industries. Whether in industry, warehouses or transportation equipment – the versatile polyamide castors and wheels are known for their stability and durability. But what should you look out for when buying polyamide wheels? In this article, we will give you an overview of the most important criteria and different types of polyamide wheels. We will answer every question around how to find the right polyamide wheel for your needs.

Why polyamide wheels?

Polyamide, a hard-wearing plastic, is particularly suitable for wheels because it is robust, abrasion-resistant and chemical-resistant. Polyamide wheels are able to carry heavy loads and run smoothly even under heavy loads. In addition, they are lightweight compared to metal wheels and can be used in many areas, from warehouse logistics to the food industry.

What common polyamide wheels exist?

There are various types of polyamide wheels that have been developed for different applications. Here is an overview of the most important types:

- Standard polyamide wheels: These are the most common and are well suited for general applications. They are hard-wearing, abrasion-resistant and have a high load-bearing capacity.

- Heavy-duty polyamide wheels: In these wheels, the polyamide is reinforced with glass fibers or other materials. This makes them particularly stable and suitable for very high loads. Ideal if you need to transport heavy loads frequently.

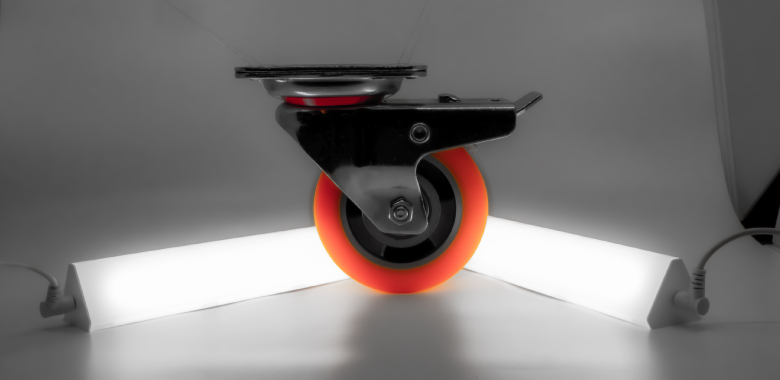

- Polyamide wheels with polyurethane or rubber tread: These wheels have a soft tread made of materials such as polyurethane or rubber. They offer better traction and are quieter when rolling, making them ideal for sensitive floors such as wood or laminate as well as noise-sensitive areas such as hospitals or offices.

Some applications require special wheels, which will not be discussed further in this article.

These tips will help you on how to find the right polyamide wheel

Before you select a polyamide wheel, you should consider which requirements need to be met in your area of application. Here are the most important criteria for finding the right polyamide wheel for your application:

Assess load capacity correctly

Polyamide wheels are available in different load capacities. If you want to move heavy loads, you should look for a wheel with a high load capacity. Consider in advance how much weight the wheel needs to carry. Add up the weight of all the objects to be transported on the wheels and divide the total weight by the number of wheels. This will tell you the minimum load capacity that the bike must be able to carry).

Consider the bearing type

When choosing the right polyamide wheel, the bearing type plays a decisive role, as it has a significant influence on the running properties.

- Slide bearings: They are characterized by their simple design and cost efficiency and are ideal for applications with lower speeds and loads.

- Ball bearings: are the best choice for maximum precision and smooth running. They are ideal for high speeds and heavy loads.

Pay attention to the ambient conditions

- Ground conditions: Consider the surface on which the wheel will be used. Polyamide wheels roll well on smooth, firm floors. Wheels with an additional tread may be more suitable for sensitive or uneven floors, as they are softer and gentler. Do you use the wheel outdoors or in wet environments? Bear in mind that polyamide can absorb moisture and affect the mechanical properties. If you expose the wheel to high levels of UV radiation, the material will become brittle and discolored more quickly. It is therefore important in these cases that the polyamide can withstand the conditions.

- Temperature range: Some polyamide wheels are suitable for use in extreme temperatures. If your area of application is hot or very cold (e.g. in ovens or cold stores), you should choose a wheel that is resistant to high temperatures.

- Resistance to chemicals: Polyamide is generally resistant to many chemicals. However, if you are using the wheels in an environment with special chemicals, find out beforehand whether the material can withstand this exposure.

Efficiency thanks to the right castor design

With the right castor design, the functionality and efficiency of transport solutions can be optimally adapted to the respective requirements. Different castor designs offer specific advantages depending on the area of application:

- Swivel casters: These swivel-mounted castors enable high maneuverability and are ideal for mobile applications where maneuverability is required.

- Fixed casters: Fixed wheels designed for straight travel and ensure stability with smooth movements.

- Wheels without housing: These wheels offer maximum flexibility as they can be individually mounted in specific applications to meet all requirements.

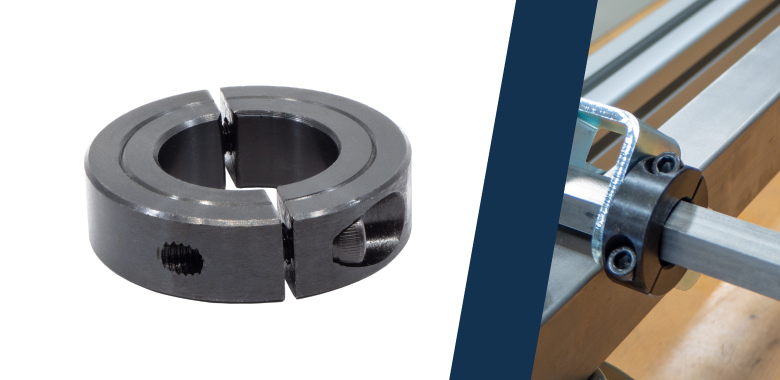

Check fastening systems and avoid bad purchases

An often underestimated but essential aspect when buying polyamide wheels is ease of installation. Make sure that the fastening systems such as screw plates, bolts or other connecting elements are compatible with your existing devices or machines. A precise fit saves time during installation and ensures that the wheels function safely and reliably. This is particularly important if the wheels are to be retrofitted or replaced in existing systems.

Test different wheel types

If you are unsure whether the standard polyamide wheel is suitable for your application, also test reinforced or rubber-coated wheels. These may offer additional benefits in terms of durability and noise reduction.

Conclusion on how to find the right polyamide wheel for your needs

Polyamide wheels are a versatile and robust choice for a variety of applications. By factoring the load capacity, surface and environment into your decision, you can find the right wheel for your requirements. Whether standard polyamide wheels for simple applications or reinforced models for heavy loads – there is a wide choice and something for every need. Take a look at our wheels & castors at your leisure!

Still unsure? Give us a call and we’ll see together which polyamide wheel is the right choice for you!