Heavy-duty levelling caster – transport large loads easily

The moving and flexible rearrangement of work equipment, machines, storage areas and workbenches required in current production processes is not always trivial. In order to also take safety aspects into account, in many cases it is necessary that the objects can be safely set down again after moving. The heavy-duty levelling caster from Sigerist are the optimal solution for this.

Move heavy furniture and machines easily with heavy-duty levelling casters

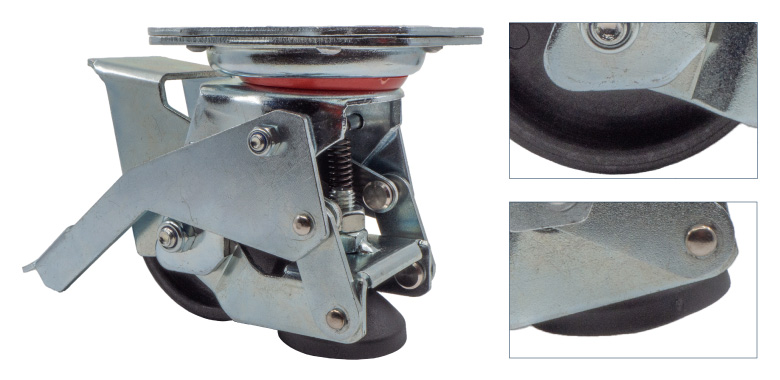

The heavy-duty levelling casters SLP 1/125 and SLK 1/125 have a load capacity of 450 kg. With four such rollers, loads of almost 2 tonnes can thus be moved. The impressively high load capacity is made possible by a reinforced housing made of galvanised steel. The ground clearance is 10 mm. However, objects on castors can also be impractical for certain applications. A machine that rolls away uncontrollably during operation can create dangerous situations. A workbench that slips during work is of little use. This is where the ergonomically triggered lifting mechanism of the lifting rollers comes into play.

Ergonomic foot pedal and safe stand

A foot-operated pedal extends the stand and triggers the caster to be placed on the integrated articulated foot. The integrated machine foot is equipped with an anti-slip sole made of non-slip NBR rubber, which enables safe operation of machines or safe working on mobile work tables. The ergonomic operation saves time and energy.

Wheel tread of the heavy-duty levelling caster

The heavy-duty levelling caster is available in two different versions. The only difference is the wheel tread used on the castors. The heavy-duty levelling caster is available with a polyurethane or polyamide wheel. The wheel tread should be selected depending on the floor conditions at the place of use.

Easy mounting of heavy-duty levelling casters

The SLP 1/125 and SLK 1/125 heavy-duty levelling casters are so popular in industry, science and commerce partly because assembly is as easy as use. This is due to the built-in standard plate, thanks to which compatibility with profile systems, machines and so on is guaranteed.

Application examples

Lifting rollers are used to make things mobile that still require a secure footing.

Here are some examples:

- Machines

- Appliances

- Apparatus

- Furniture

- Kitchen islands

- Table trolleys/transport trolleys

- Workbenches or joiner’s benches

- Work tables

Have we aroused your interest? Contact us now by e-mail or phone and let us advise you without obligation.